The Tylok Story: Built the Right Way, Since the Beginning

Long before modern CNC machines filled the shop floor and digital drawings replaced drafting tables, Tylok began with something far simpler – and far more powerful: a belief that American-made products, built with care, could outperform anything else on the market.

From the very beginning, Tylok was created to solve real problems. In industries where pressure, precision, and performance mattered, customers needed fittings they could trust. Not just parts that worked on paper – but parts that worked in the real world, day after day, system after system.

So Tylok got to work.

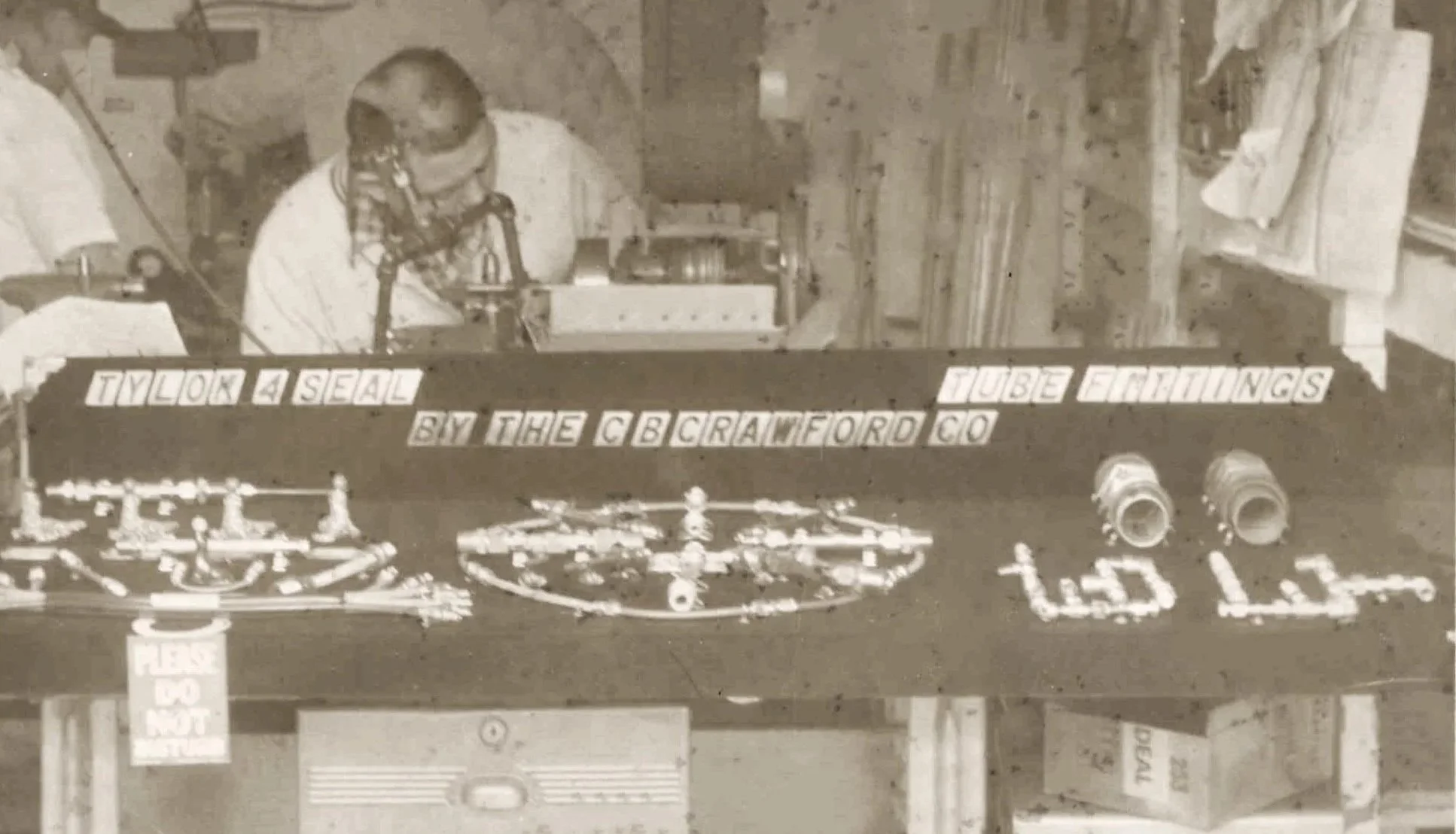

A Foundation of Craftsmanship

In the early days, Tylok was built by hands-on machinists and problem-solvers. Every fitting represented hours of careful machining, inspection, and pride. These weren’t mass-produced commodities. They were purpose-built components, designed to perform in demanding environments.

That commitment to craftsmanship became the company’s backbone. As Tylok grew, that same mindset carried forward—hire skilled people, invest in better equipment, and never compromise when it comes to quality.

Growing with Industry

As manufacturing, instrumentation, and fluid system technology evolved, so did Tylok. New industries brought new challenges. Higher pressures. Tighter tolerances. More complex applications.

Instead of chasing trends, Tylok leaned into engineering.

By building in-house design and manufacturing capabilities, the company positioned itself to innovate, customize, and refine. It wasn’t about selling fittings. It was about building solutions. Solutions that installers trusted. Solutions engineers could spec with confidence. Solutions that quietly did their job, year after year.

Where Quality Becomes a Culture

Over time, quality stopped being just a department. It became part of the culture.

From the moment raw material enters the facility to the final inspection before shipping, every step reflects a single goal: deliver products customers never have to second-guess. That mindset has guided investments in inspection equipment, testing processes, training, and continuous improvement.

It’s why customers come back.

It’s why relationships last decades.

It’s why Tylok’s name is stamped on products that operate in critical systems across countless industries.

More Than a Manufacturer

Tylok’s story isn’t only about machines and metal. It’s about people.

The engineers who refine designs.

The machinists who hold impossibly tight tolerances.

The quality teams who verify every detail.

The sales and support teams who work directly with customers to solve problems.

Together, they’ve shaped Tylok into more than a fitting manufacturer. They’ve built a partner—one rooted in trust, accountability, and the belief that doing things right still matters.

Still Writing the Story

Today, more than 70 years after the first Tylok fittings were produced, the company stands stronger than ever. With modern technology, expanded capabilities, and a new generation of skilled professionals, Tylok continues to evolve—without losing sight of what started it all.

American manufacturing.

Engineering-driven solutions.

Relentless quality.

The tools may have changed. The facility may have grown. But the heart of Tylok remains exactly the same.

And the story is still being written.